Distribution networks may be classified as either meshed or radial. However, it is customary to operate meshed networks in radial fashion with the help of mechanically operated switches (Gönen, 1986). It is well understood that radial networks are less reliable than interconnected networks but distribution engineers have preferred them because they use simple, inexpensive protection schemes, e.g. over-current protection. Distribution engineers have traditionally argued that in meshed distribution networks operated in radial fashion, most consumers are brought back on supply a short time after the occurrence of a fault by moving the network's open points. Open-point movements are carried out by re-switching operations.

Traditional construction and operation practices served the electricity distribution industry well for nearly a century. However, the last decade has seen a marked increase in loads that are sensitive to poor quality electricity supply. Some large industrial users are critically dependent on uninterrupted electricity supply and suffer large financial losses as a result of even minor lapses in the quality of electricity supply (Hingorani, 1995).

These factors coupled with the ongoing deregulation and open access electricity markets, where large consumers may shop around for competitively priced, high-quality electricity, have propelled the distribution industry into unprecedented change. On the technical front, one major development is the incorporation of power electronics controllers in the distribution system to supply electricity with high quality to selected customers. The generic, systematic solution being considered by the utility to counter the problem of interruptions and low power quality at the end-user level is known as Custom Power. This is the low voltage counterpart of the more widely known FACTS technology.

Although FACTS and custom power initiatives share the same technological base, they have different technical and economic objectives (Hingorani and Gyugyi, 2000). Flexible alternating current transmission systems controllers are aimed at the transmission level whereas Custom Power controllers are aimed at the distribution level, in particular, at the point of connection of the electricity distribution company with clients with sensitive loads and independent generators. Custom Power focuses primarily on the reliability and quality of power flows. However, voltage regulation, voltage balancing and harmonic cancellation may also benefit from this technology.

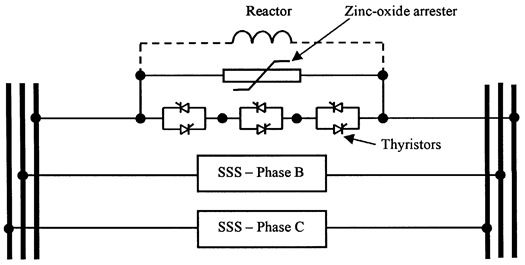

The STATCOM, the DVR and the solid state switch (SSS) are the best known Custom Power equipment. The STATCOM and the DVR both use VSCs, but the former is a shunt connected device which may include the functions of voltage control, active filtering and reactive power control. The latter is a series connected device which precisely compensates for waveform distortion and disturbances in the neighbourhood of one or more sensitive loads. Figure 1.10 shows the schematic representation of a three-phase STATCOM. Figure 1.14 shows that of a DVR and Figure 1.15 shows one phase of a three-phase thyristor-based SSS.

The STATCOM used in Custom Power applications uses PWM switching control as opposed to the fundamental frequency switching strategy preferred in FACTS applications. PWM switching is practical in Custom Power because this is a relatively low power application.

On the sustainable development front, environmentally aware consumers and government organizations are providing electricity distribution companies with a good business opportunity to supply electricity from renewable sources at a premium. The problem yet to be resolved in an interconnected system with a generation mix is how to comply with the end-user's desire for electricity from a renewable source. Clearly, a market for renewable generation has yet to be realized.

Utilization

The customers of electricity vendors may be classified as industrial, commercial and domestic (Weedy, 1987). In industrialized societies, the first group may account for as much as two fifths of total demand. Traditionally, induction motors have formed the dominant component in the vast array of electric equipment found in industry, both in terms of energy consumption and operational complexity. However, computer-assisted controllers and power electronics-based equipment, essential features in modern manufacturing processes, present the current challenge in terms of ensuring their trouble-free operation. This equipment requires to be supplied with high quality electricity.

Some loads draw constant current from the power system and their operation may be affected by supply voltage and frequency variations. Examples of these loads are:

- induction motors

- synchronous motors

- DC motors.

Other types of loads are less susceptible to voltage and frequency variations and exhibit a constant resistance characteristic:

- incandescent lighting

- heating.

- colour TV sets

- microwave ovens

- energy saving lamps

- computer equipment

- industrial variable speed motor drives

- battery recharging stations.

Electric energy storage is an area of great research activity, which over the last decade has experienced some very significant breakthroughs, particularly with the use of superconductivity and hydrogen related technologies. Nevertheless, for the purpose of industrial applications it is reasonable to say that, apart from pumped hydro storage, there is very little energy storage in the system. Thus, at any time the following basic relation must be met:

Generation = Demand + Transmission Losses

Power engineers have no direct control over the electricity demand. Load shedding may be used as a last resort but this is not applicable to normal system control. It is normally carried out only under extreme pressure when serious faults or overloads persist.

previous Power Transmission

next The dynamic response of electrical power networks

0 comments:

Post a Comment