Reactive power control

In an ideal AC power system the voltage and frequency at every supply point would be constant and free from harmonics, and the power factor would be unity. In particular these parameters would be independent of the size and characteristics of consumers' loads. In an ideal system, each load could be designed for optimum performance at the given supply voltage, rather than for merely adequate performance over an unpredictable range of voltage. Moreover, there could be no interference between different loads as a result of variations in the current taken by each one (Miller, 1982).

In three-phase systems, the phase currents and voltages must also be balanced ( Unbalance causes negative-sequence current which produces a backward-rotating field in rotating AC machines, causing torque fluctuations and power loss with potential overheating). The stability of the system against oscillations and faults must also be assured. All these criteria add up to a notion of power quality. A single numerical definition of power quality does not exist, but it is helpful to use quantities such as the maximum fluctuation in rms supply voltage averaged over a stated period of time, or the total harmonic distortion (THD), or the 'availability' (i.e. the percentage of time, averaged over a period of, say, a year, for which the supply is uninterrupted).

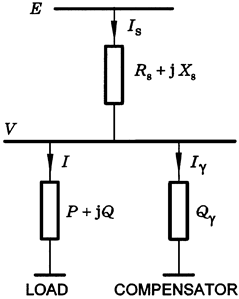

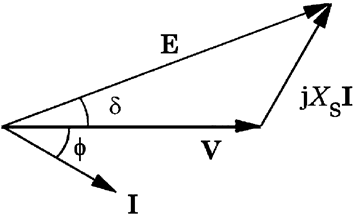

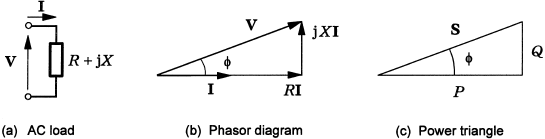

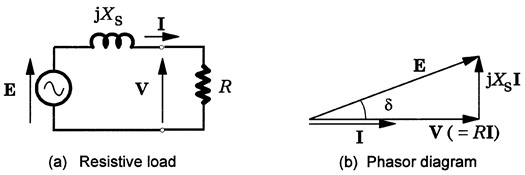

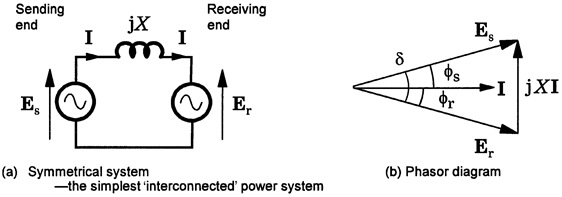

The maintenance of constant frequency requires an exact balance between the overall power supplied by generators and the overall power absorbed by loads, irrespective of the voltage. However, the voltage plays an important role in maintaining the stability of power transmission, as we shall see. Voltage levels are very sensitive to the flow of reactive power and therefore the control of reactive power is important. This is the subject of reactive compensation. Where the focus is on individual loads, we speak of load compensation, and this is the main subject of this chapter along with several related fundamental topics of power systems engineering.

Load compensation is the management of reactive power to improve the quality of supply at a particular load or group of loads. Compensating equipment — such as power-factor correction equipment—is usually installed on or near to the consumer's premises. In load compensation there are three main objectives:

- power-factor correction

- improvement of voltage regulation ('Regulation' is an old-fashioned term used to denote the variation of voltage when current is drawn from the system)

- load balancing.

Power-factor correction and load balancing are desirable even when the supply voltage is 'stiff': that is, even when there is no requirement to improve the voltage regulation. Ideally the reactive power requirements of a load should be provided locally, rather than drawing the reactive component of current from a remote power station. Most industrial loads have lagging power factors; that is, they absorb reactive power. The load current therefore tends to be larger than is required to supply the real power alone. Only the real power is ultimately useful in energy conversion and the excess load current represents a waste to the consumer, who has to pay not only for the excess cable capacity to carry it, but also for the excess Joule loss in the supply cables. When load power factors are low, generators and distribution networks cannot be used at full efficiency or full capacity, and the control of voltage throughout the network can become more difficult. Supply tariffs to industrial customers usually penalize low power-factor loads, encouraging the use of power-factor correction equipment.

In voltage regulation the supply utilities are usually bound by statute to maintain the voltage within defined limits, typically of the order of 15% at low voltage, averaged over a period of a few minutes or hours. Much more stringent constraints are imposed where large, rapidly varying loads could cause voltage dips hazardous to the operation of protective equipment, or flicker annoying to the eye.

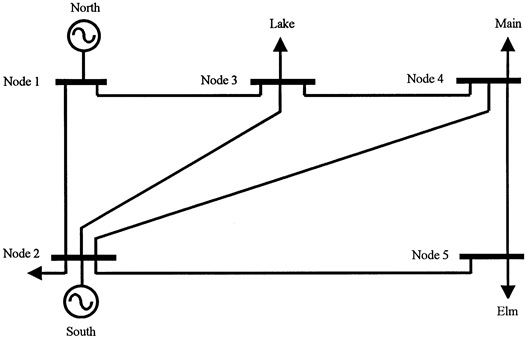

The most obvious way to improve voltage regulation would be to 'strengthen' the power system by increasing the size and number of generating units and by making the network more densely interconnected. This approach is costly and severely constrained by environmental planning factors. It also raises the fault level and the required switchgear ratings. It is better to size the transmission and distribution system according to the maximum demand for real power and basic security of supply, and to manage the reactive power by means of compensators and other equipment which can be deployed more flexibly than generating units, without increasing the fault level.

Similar considerations apply in load balancing. Most AC power systems are three-phase, and are designed for balanced operation. Unbalanced operation gives rise to components of current in the wrong phase-sequence (i.e. negative- and zero-sequence components). Such components can have undesirable effects, including additional losses in motors and generating units, oscillating torque in AC machines, increased ripple in rectifiers, malfunction of several types of equipment, saturation of transformers, and excessive triplen harmonics and neutral currents [Triplen (literally triple-n) means harmonies of order 3n, where n is an integer].

The harmonic content in the voltage supply waveform is another important measure in the quality of supply. Harmonics above the fundamental power frequency are usually eliminated by filters. Nevertheless, harmonic problems often arise together with compensation problems and some types of compensator even generate harmonics which must be suppressed internally or filtered.

The ideal compensator would:

- supply the exact reactive power requirement of the load;

- present a constant-voltage characteristic at its terminals; and

- be capable of operating independently in the three phases.

In practice, one of the most important factors in the choice of compensating equipment is the underlying rate of change in the load current, power factor, or impedance. For example, with an induction motor running 24 hours/day driving a constant mechanical load (such as a pump), it will often suffice to have a fixed power-factor correction capacitor. On the other hand, a drive such as a mine hoist has an intermittent load which will vary according to the burden and direction of the car, but will remain constant for periods of one or two minutes during the travel. In such a case, power-factor correction capacitors could be switched in and out as required. An example of a load with extremely rapid variation is an electric arc furnace, where the reactive power requirement varies even within one cycle and, for a short time at the beginning of the melt, it is erratic and unbalanced. In this case a dynamic compensator is required, such as a TCR or a saturated-reactor compensator, to provide sufficiently rapid dynamic response.

Steady-state power-factor correction equipment should be deployed according to economic factors including the supply tariff, the size of the load, and its uncompensated power factor. For loads which cause fluctuations in the supply voltage, the degree of variation is assessed at the 'point of common coupling' (PCC), which is usually the point in the network where the customer's and the supplier's areas of responsibility meet: this might be, for example, the high-voltage side of the distribution transformer supplying a particular factory.

Loads that require compensation include arc furnaces, induction furnaces, arc welders, induction welders, steel rolling mills, mine winders, large motors (particularly those which start and stop frequently), excavators, chip mills, and several others. Non-linear loads such as rectifiers also generate harmonics and may require harmonic filters, most commonly for the 5th and 7th but sometimes for higher orders as well. Triplen harmonics are usually not filtered but eliminated by balancing the load and by trapping them in delta-connected transformer windings.

The power-factor and the voltage regulation can both be improved if some of the drives in a plant are synchronous motors instead of induction motors, because the synchronous motor can be controlled to supply (or absorb) an adjustable amount of reactive power and therefore it can be used as a compensator. Voltage dips caused by motor starts can also be avoided by using a 'soft starter', that is, a phase-controlled thyristor switch in series with the motor, which gradually ramps the motor voltage from a reduced level instead of connecting suddenly at full voltage.

| Load | Limits of voltage fluctuation |

| Large motor starts | 1-3% depending on frequency |

| Mine winders, excavators, large motor drives | 1-3% at distribution voltage level

0.5 – 1.5% at transmission voltage level |

| Welding plant | 1/4-2% depending on frequency |

| Induction furnaces | Up to 1% |

| Arc furnaces | <1/2% |

Table 2.1 Typical voltage fluctuation standards.

-

Continuous and short-time reactive power requirements.

-

Rated voltage and limits of voltage variation.

-

Accuracy of voltage regulation required.

-

Response time of the compensator for a specified disturbance.

-

Maximum harmonic distortion with compensator in service.

-

Performance with unbalanced supply voltages and/or with unbalanced load.

-

Environmental factors: noise level; indoor/outdoor installation; temperature, humidity, pollution, wind and seismic factors; leakage from transformers, capacitors, cooling systems.

-

Cabling requirements and layout; access, enclosure, grounding; provision for future expansion; redundancy and maintenance provisions.

-

protection arrangements for the compensator and coordination with other protection systems, including reactive power limits if necessary.

-

Energization procedure and precautions.

|

Table 2.2 Factors to consider in specifying compensating equipment.

Standards for the quality, of supply. One very noticeable effect of supply voltage variations is flicker especially in tungsten filament lamps. Slow variations of up to 3% may be tolerable, but rapid variations within the range of maximal visual sensitivity (between I and 25 Hz) must be limited to 0.25% or less. A serious consequence of undervoltage is the overcurrent that results from the fact that AC motors run at a speed which is essentially determined by the frequency, and if the voltage is low the current must increase in order to maintain the power. On the other hand, overvoltage is damaging to insulation systems.

Table 2.1 gives an idea of the appropriate standards which might be applied in different circumstances, but local statutes and conditions should be studied in each individual case.

Specification of a load compensator. Some of the factors which need to be considered when specifying a load compensator are summarized in Table 2.2.

Conventions used in power engineering

In power engineering it is helpful to have a set of conventions for symbols. Unfortunately many people disregard conventions, and this causes confusion. There is no universal standard, but the simple conventions given in Table 2.3 are widely used, practical, and consistent with most classic textbooks.

| Type | What is meant | Examples |

| Lower-case italic | Instantaneous values

| V, i |

| Upper-case italic |

| RMS values or DC values |

| Resistance, reactance, and impedance magnitude |

| Inductance and capacitance |

|

|

| Upper-case boldface roman | Phasors

Impedance | V, I

Z |

Table 2.3 Font and symbol conventions

In handwritten work, you can't really use boldface, so use a bar or arrow or tilde — preferably

over the symbol, e.g.

Subscripts can be roman or italic; it is a matter of style

In three-phase systems, various conventions are used for the subscripts used to denote the three phases. In Europe (particularly Germany): U, V, W. In the UK: R, Y, B (for red, yellow, blue), or a, b, c. In the United States: a, b, c or A, B, C. You will also see I, 2, 3 used: this seems an obvious choice, but if you are working with symmetrical components these subscripts can be confused with the positive, negative, and zero-sequence subscripts I, 2, 0 (sometimes +, -, 0). The best advice is to be very careful!

Never confuse phasor values with scalar values!

| Examples |

| Typeset | Comment |

| V=RI | RMS AC; or DC |

| V=jXI | V and I are phasores

X is a scalar (reactance)

jX is an impedance (complex) |

| Z=R+jX | Z is complex (impedance)

R is scalar (resistance)

X is scalar (reactance) |

| v=Vmcosωt | v is an instantaneous value

Vm is a fixed scalar value |

previous

The role of computers in the monitoring, control and planning of power networks

next Basic source/load relationships